Eleventh and 12th grade physics classes at Byram Hills High School got a peek into the state’s largest infrastructure project when the New NY Bridge educational outreach team came to their school this academic year. “We asked them to focus on the engineering aspects of it although some science students were there,” BHHS teacher Paul Beeken said.

The presentation included the politics of getting a megaproject started. “One fascinating concept for us (students) was how to get a project like this in place,” Beeken said.

This year one of BHHS’s classes built a truss build from balsa wood and was challenged to see how much it can carry versus the weight of the bridge itself. “With this in mind, they have an understanding it’s a tradeoff: cost of materials and how heavy is the bridge versus how much can it carry,” he said.

Beeken requested the presentation focus on engineering and the stress factors: what goes into building the roadway, the technologies needed to lift roadway and how the super crane was able to lift the weights it did as he’d finished a unit on forces including weights and pulleys.

When the kids asked Marcy where he got his degree, he told them he’s not an engineer and explained his background. “That was very valuable,” Beeken said, “because the kids could see someone who wasn’t an engineer but who was still very articulate about all the different facets of the project.”

Engineering is only one part of the project, he noted. “While maybe one-tenth of the class will become engineers, it’s important to have a basic literacy to more easily navigate the subject.”

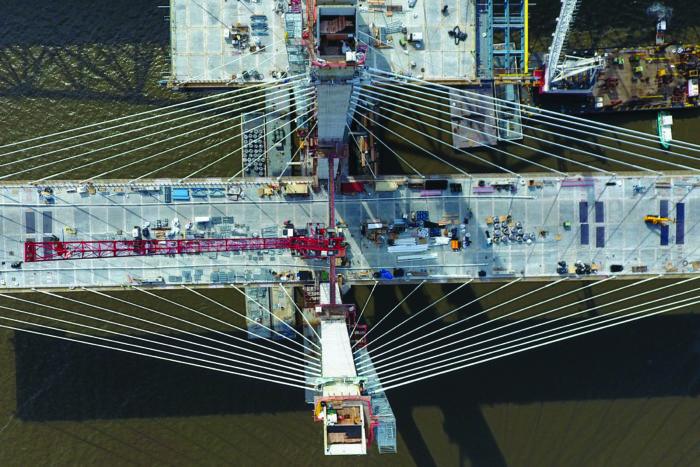

Months after the new bridge’s eight iconic towers were completed (in December) the super crane resumed setting structural steel on the eastbound span utilizing a different process. Assemblies lifted from the northern side of the westbound were moved to a floating barge between the two new spans and then fitted across the eastbound span’s concrete piers.

Anti-climb tensile mesh fencing will line both sides of both spans and the walking/bicycle path; steel mesh safety netting will be below each of the six belvederes. Earlier this year, an aesthetic LED (light emitting diodes) hour-long system test set more than 20 piers on the westbound Rockland awash in bright colors.

When fully installed, the 2,700 color lights and 500 white lights from Philips Lighting, the same company that brightens Madison Square Garden, will also illuminate the eight iconic towers and stay cables. With a predicted 100,000-hour lifespan (three times that of conventional lamps), the lights will use roughly 75 percent less energy.

As of a mid-April, date, all 96 stay cables–ranging from 190 to 623 feet long–for the westbound span and one-third (32) for the eastbound span are attached to their respective towers and tensioned to structural steel. More than 120 girder assemblies have been installed on both spans. Ongoing work includes installing concrete noise barrier panels along the northbound Thruway in South Nyack this week and installing transparent acrylite noise barriers on the Rockland approach on the soon-to-open westbound span and installing overhead gantries with electronic signage about lane use, exits and other helpful information.

“Before the (Tappan Zee) bridge was built there was nothing there, so no one had any expectations about what a bridge would do,” Beeken said. “Now (building a bridge today) is 10 times more difficult because people need that bridge and depend upon it. You want to build a new one, so the logistics of being able to build a new bridge without ever shutting down the old one presents challenges.”

Two-way traffic will temporarily switch to the new westbound span’s eight lanes by spring/summer. Crews will then dismantle the current bridge so the eastbound span can be completed and attached to the Westchester and Rockland landings.

The full bridge and its walking/bicycle path is expected to open in 2018.

PHOTOS CREDIT NYSTA